Understanding the Differences Between MIG, TIG, and Spot Welding

Welding is a fundamental process in many industries, enabling the joining of two or more pieces of metal by melting materials and fusing them. There are numerous welding processes available, each with unique advantages, disadvantages, and applications. In this comprehensive guide, we will delve into the differences between MIG, TIG, and Spot welding, discussing the factors to consider when choosing a welding process.

Understanding Welding

Welding is a versatile process used to join a wide variety of metals. It's a permanent process, meaning the metals are joined and cannot be separated. Multiple different welding processes exist, each with its own set of advantages and disadvantages. The right welding process for a particular job will depend on the type of metal, the thickness of the metal, and the desired strength of the joint.

MIG Welding

Metal Inert Gas (MIG) welding is a popular welding process used with a variety of metals. MIG welding uses a wire electrode continuously fed into the weld area. An electric arc melts the electrode, and the molten metal from the electrode and the base metal fuse.

MIG welding is a relatively straightforward process to learn and can be used to weld an abundance of metals in all sorts of thicknesses. It is also a fast and efficient welding process. However, MIG welding can produce a spatter, and the welds may not be as strong as TIG welds. Despite these drawbacks, MIG welding is often chosen for its speed and affordability, making it a popular choice for many applications.

TIG Welding

Tungsten Inert Gas (TIG) welding is a more versatile welding process than MIG welding. TIG welding can weld all sorts of metals, including stainless steel, aluminum, and titanium. It can also weld thinner metals than MIG welding.

TIG welding uses a non-consumable tungsten electrode surrounded by an inert gas shield. The arc melts the base metal and can fuse both pieces when tightly fitted. Additional material is needed when the parts can't fit tightly, and a filler rod supplies additional metal to the joint. TIG welding produces very clean welds with high strength. However, TIG welding is a difficult process to learn and requires more skill to operate. Despite being costly and requiring more advanced skills, TIG welding achieves optimal results in strength and aesthetics.

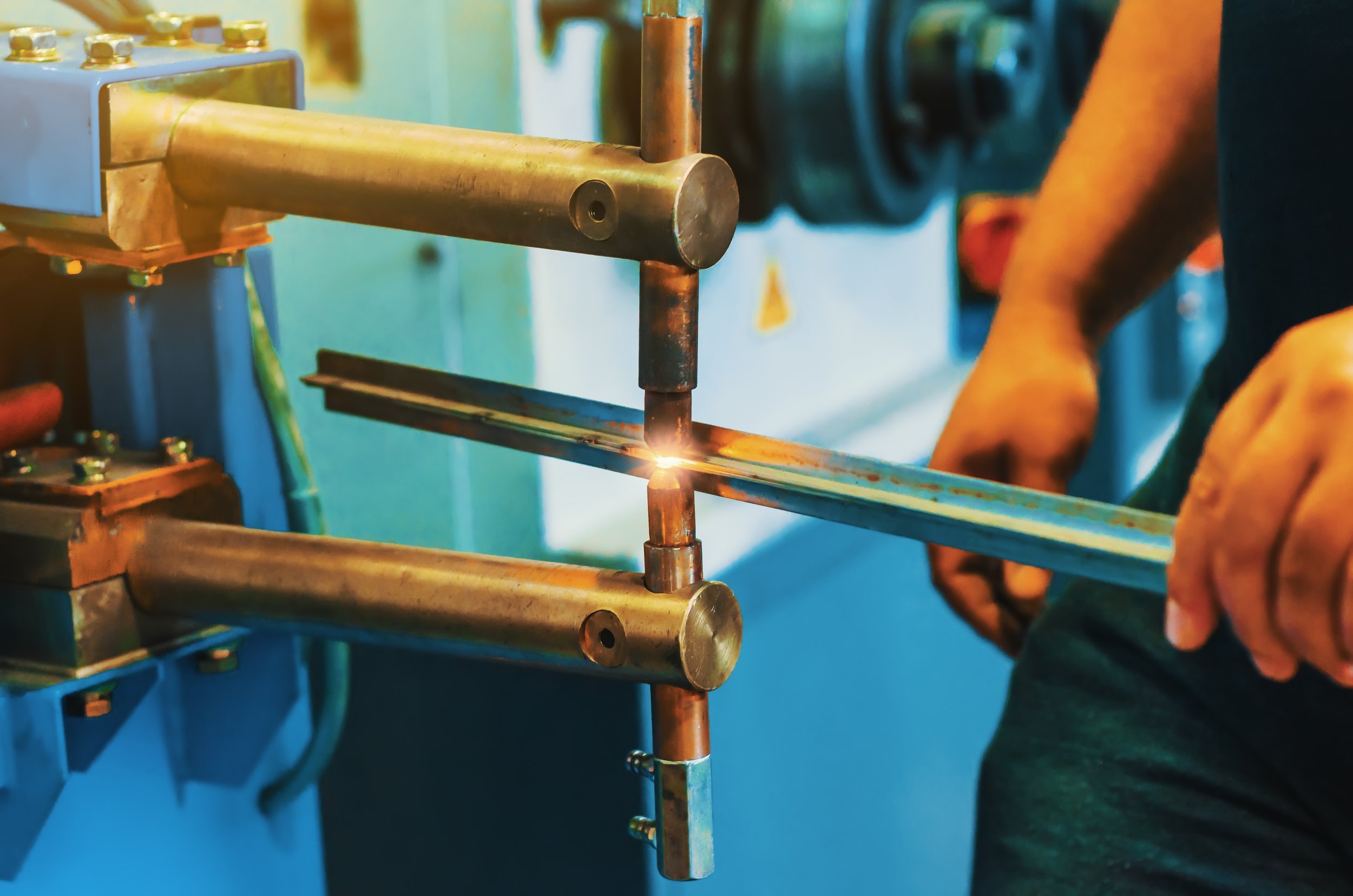

Spot Welding

Spot welding is a type of resistance welding used to join two or more pieces of metal by heat and pressure. Spot welding is a fast and efficient welding process used in mass production.

Spot welding uses two electrodes pressed against the metal pieces to join. When an electric current passes through the electrodes, the metal pieces heat up and fuse. Spot welding is not as strong as other welding processes, but it is a cost-effective way to join metal pieces. It's popular for its speed and the minimal supplies needed.

Comparing MIG, TIG, and Spot Welding

When comparing MIG, TIG, and Spot welding, several factors come into play. MIG welding is fast, efficient, and easy to learn, but it can produce splatter, and the welds may not be as strong as TIG welds. TIG welding produces clean, strong welds and can weld a wider variety of metals. Spot welding is fast, efficient, and cost-effective, but it is not as strong as other welding processes.

Factors to Consider Between MIG, TIG, and Spot Welding

Choosing the right welding process can make a dramatic difference in the outcome of your project. Whether you're working on a small DIY project or a large industrial application, understanding the factors that influence the choice between MIG, TIG, and Spot Welding is crucial.

Type of Metal

The type of metal welded is one of the most important factors to consider. MIG welding is versatile and works well on multiple metals, including steel, stainless steel, and aluminum. TIG welding, on the other hand, is more advanced and can handle a wider variety of metals, including those that are non-ferrous, like copper and titanium. Spot welding mainly operates on sheet metal, such as those used in automotive bodywork.

Thickness of the Metal

The thickness of the metal also plays a significant role in choosing the right welding process. MIG welding works well with thicker materials due to its ability to deposit a large amount of filler material at a fast rate. TIG welding, with its precise and controlled process, is better suited for thinner materials. Spot welding is typically used for joining thin sheets of metal, where other welding methods might burn through the material.

Desired Strength of the Joint

The strength of the joint is another crucial factor. TIG welding often produces the strongest and highest quality welds due to its precision and control. MIG welding, while not as strong as TIG, still offers a robust joint suitable for many applications. Spot welding, while efficient and quick, does not provide the same level of strength and is best used in applications where high strength is not required.

Cost of the Welding Process

Cost is always a consideration in any project. MIG welding is generally more affordable, both in terms of equipment and operation. TIG welding, while offering superior results, is more costly due to the need for more expensive equipment and gases. Spot welding can be cost-effective, especially in high-volume production settings.

Practical Applications of MIG, TIG, and Spot Welding in a Metal Fabrication Facility

In a metal fabrication facility, the choice of welding process can significantly impact the quality, efficiency, and cost-effectiveness of the operations. Here, we will discuss specific examples of fabrication projects where MIG, TIG, and Spot welding are most suitable.

MIG Welding Projects

MIG welding, known for its versatility and speed, is commonly used in a variety of fabrication projects:

Structural Steel Projects: MIG welding works well with the fabrication of structural steel components due to its ability to handle thicker materials and its speed of operation. This includes the construction of beams, columns, and frames for buildings and bridges.

Heavy Equipment Manufacturing: MIG welding is also commonly used in the manufacturing of heavy equipment like tractors, bulldozers, and cranes. Its ability to quickly lay down strong welds makes it ideal for these large-scale projects.

Sheet Metal Products: MIG welding also works great for sheet metal products, such as HVAC ductwork, metal cabinets, and enclosures. Its ease of use and speed make it a good choice for these types of projects.

TIG Welding Projects

TIG welding, known for its precision and high-quality welds, is ideal for projects that require a high level of detail and strength:

Aerospace Components: In industries like aerospace, where the strength and integrity of each component are crucial, TIG welding is often the preferred method. This includes the fabrication of engine parts, fuselage components, and landing gear.

Automotive Parts: TIG welding is also commonly used for automotive parts, especially those made from non-ferrous metals like aluminum and titanium. This includes engine components, exhaust systems, and body parts.

Precision Instruments: TIG welding's precision makes it ideal for the fabrication of precision instruments and devices. This includes medical devices, scientific instruments, and high-tech equipment.

Spot Welding Projects

Spot welding, with its speed and efficiency, is often used in high-volume production settings:

Automotive Assembly: Spot welding is common in the automotive industry, particularly in assembling the bodywork of vehicles. It's quick, efficient, and requires minimal supplies.

Sheet Metal Products: Spot welding regularly combines sheets of metal. This includes the production of metal cabinets, enclosures, and HVAC components.

Electronics Manufacturing: Electronics is another place you will see spot welding. The technique can join small pieces of metal without damaging the important components.

MIG, TIG, and Spot welding are all popular welding processes that have their own advantages and disadvantages. The right welding process for a particular job will depend on the type of metal to be welded, the thickness of the metal, the desired strength of the joint, the cost of the welding process, and the skill level of the welder. By understanding the differences between these welding processes, you can choose the one that best suits your needs.

Contact Us

If you're interested in working with Western Design & Fabrication on your next welding project, please contact us today. We would be happy to discuss your project and how we can help you achieve your goals.